Digital orthodontics has revolutionized the way we create smiles — and at Clear Moves Aligners, precision, efficiency, and predictability define every stage of our treatment process. From the first STL file to the final aligner delivery, our workflow is engineered for accuracy and consistency, empowering dentists and orthodontic professionals to deliver confident smiles with total control.

Below, we take you through our complete end-to-end workflow — the same process that ensures every Clear Moves case is planned, produced, and delivered to perfection.

Every successful treatment begins with accurate data.

Digital Scans: The workflow starts with high-resolution intraoral scans of the patient’s upper and lower arches, including bite registration.

File Validation: Scans are exported in STL format and verified for mesh integrity to prevent distortion during digital modeling.

Clinical Data Integration: Clinical notes, X-rays, and patient photos are linked to the STL data to provide a holistic view of dental health and occlusion.

Tip: At Clear Moves, our system automatically checks STL quality before it enters planning — reducing rework and ensuring every plan starts on the right foot.

Once the data is validated, our clinical planning team evaluates case suitability.

Complexity Check: Each case is classified by movement type — spacing, crowding, crossbite, deep bite, or other specific conditions.

Feasibility Analysis: Using digital models, we assess whether aligner therapy can predictably achieve the desired results.

Treatment Goals: Patient expectations are matched with realistic, data-driven outcomes.

Tip: Our internal “Predictability Index” helps clinicians gauge the treatment’s difficulty level before planning begins, supporting transparency and confidence at every stage.

This is where the transformation truly begins.

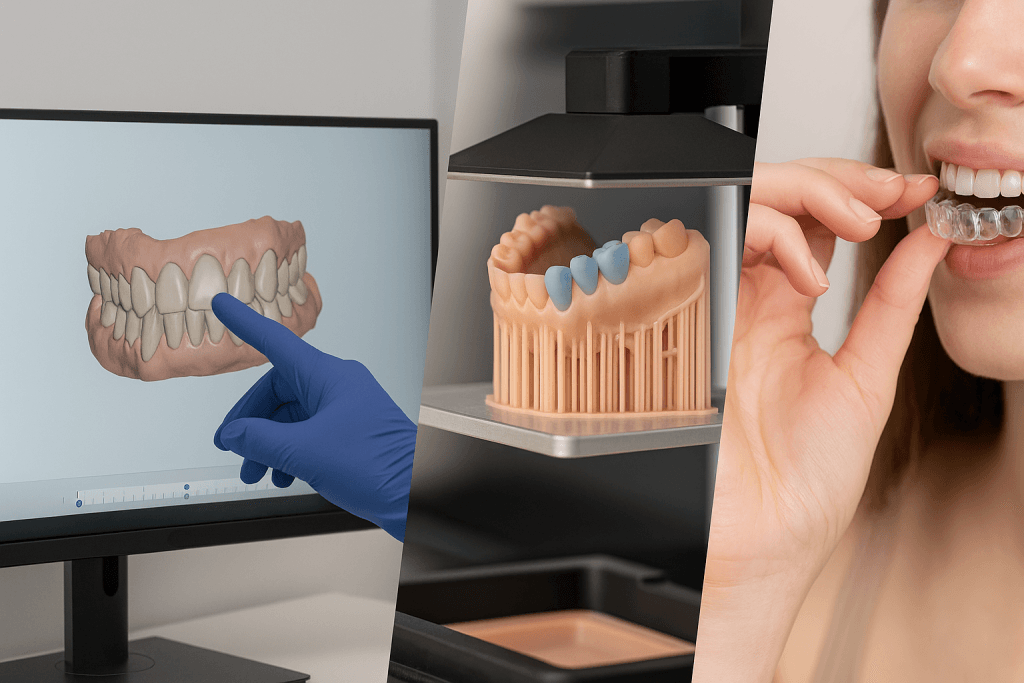

Software Integration: The STL files are uploaded to our proprietary digital planning system.

Segmentation: Each tooth is individually separated with millimeter-level accuracy.

Movement Staging: Teeth are virtually moved in safe, controlled increments — generally up to 0.2 mm per aligner.

Attachments & IPR Planning: If required, attachment placement and interproximal reduction are designed to optimize control and movement precision.

Virtual Simulation: A 3D visualization of the final outcome is generated and shared with the treating dentist for review and approval.

Tip: Our planners use biomechanical algorithms to simulate realistic tooth movement patterns — ensuring planned shifts are clinically achievable and biologically safe.

After digital approval, the case moves to manufacturing — where technology meets craftsmanship.

3D Printing: Each stage model is printed with medical-grade accuracy to serve as the forming base.

Thermoforming: Our FDA- and CE-approved multi-layer TPU sheets are used to thermoform clear aligners that provide both flexibility and strength.

Finishing & Polishing: Each aligner is trimmed with laser precision and hand-finished to ensure comfort and edge smoothness.

Quality Control: Every aligner undergoes dimensional verification, batch tracking, and visual inspection before packaging.

Tip: At Clear Moves Aligners, each aligner is laser-etched with a unique case ID to ensure traceability and clinical accountability.

Once fabrication is complete, the aligner set is packaged and shipped to the clinic or patient.

Packaging: Aligner sets are securely packed in hygienic, branded boxes with wear sequence clearly marked.

Clinical Fitting: Dentists verify the fit of the first aligner and provide the patient with wear and care instructions.

Education: Our aligner starter guide educates patients on wear duration (20–22 hours/day), cleaning protocols, and handling tips.

Tip: The “Clear Moves Welcome Kit” includes chewies, a case, and a cleaning foam — designed to enhance the patient’s compliance and comfort.

Treatment success depends on precision — and consistency.

Regular Monitoring: Progress scans or check-ins are conducted at 6–8-week intervals.

Tracking Fit: Dentists compare the actual tooth positions with the predicted digital plan.

Refinement Stage: If movement is off-track, a quick re-scan allows our planning team to generate refinement aligners with updated movement goals.

Tip: Digital refinements at Clear Moves are free for the first request within a standard treatment — keeping your cases efficient and predictable.

Once the desired smile is achieved, retention is the key to long-term success.

Final Scan & Verification: The last aligner is compared against the original goal to confirm full correction.

Retainer Design: Clear retainers are fabricated using the same high-clarity TPU sheets for comfort and longevity.

Maintenance Guidance: Patients receive post-treatment instructions to maintain their results.

Tip: Every Clear Moves case includes two retainers with the final delivery, ensuring your patients stay confident long after treatment ends.

All digital records — including STL files, treatment plans, refinements, and final scans — are stored securely in our system.

This archive allows clinics to:

Retrieve old cases easily.

Analyze performance metrics like average refinement rates.

Maintain complete traceability for regulatory compliance.

Tip: Our partner portal allows clinicians to access every stage of their patient’s journey — from the initial upload to the final smile delivery.

Every smile begins with precision — and ends with perfection.

Our end-to-end workflow, from STL to Smile, is designed to merge digital innovation with clinical accuracy. By maintaining control at every step — from scan validation to aligner fabrication — we ensure that both dentists and patients experience predictability, comfort, and satisfaction.

When expertise meets technology, the result is clear: a better, faster, more confident smile — the Clear Moves way.

© 2025 Clear Moves Aligners All Rights Reserved